Automation In Steel Manufacturing

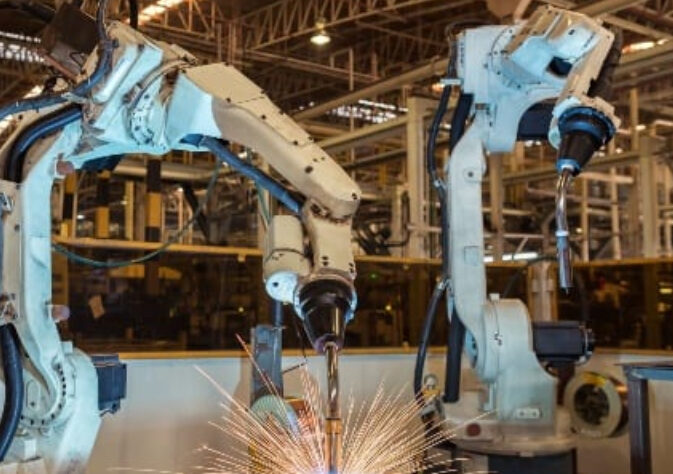

Efficiency is an important factor in manufacturing. Efficiency along with consistent quality are game-changers for most industries in the manufacturing sector. A fabricator from a top company in metal fabrication, Singapore, states that automation improves efficiency, quality and improves safety in the manufacturing process. Mild steel and other metal manufacturing processes will involve highly dangerous steps that can be tough to involve workers. Robotics is a technology that helps create a smart manufacturing process that is efficient and advanced. Steel production is already a highly automated process that is filled with intelligent systems. These intelligent systems can also be considered robots, making the whole steel production easy for the workers.

Earlier, robots were used in casting machines to measure gaps and immersion probes. With an increase in robotic technology, manufacturers aim to make the complete factory automated to keep the environment safe for the workers. With the evolution of technology, factories and shop floors now have artificial intelligence, laser equipment and cameras.

Robotics In Metal Fabrication

Metal fabrication involves processes like casting, cutting, and rolling. It also involves finishing, logistics and material handling. It is a process that involves man, machines and materials that requires efficiency, consistency and quality. Technology was a part of the metal fabrication industry for decades. Initially, it involved the implementation of CNC and 2D cutting of the stock material.

There were several challenges in implementing robotics in the metal fabrication industry. Mild steel fabrications were not always repetitive or precise, while robotics required repetitive tasks that were always precise. Robots do make the whole production agile, efficient, flexible and economical. However, when it comes to metal fabrication, the reprogramming of robots for every application proved very costly. Metal fabrication is not a small batch type of business. Each wedding is unique.

Standard automation tools were introduced to improve efficiency in the manufacturing process, which helped improve the programming time for each unique welding. Such programming tools have helped develop robots with more capabilities that are beneficial for fabrication. Simulation of robotic arcs for cutting and welding applications in 2D and 3D space has been a game-changer. With programming tools, you can now import a CAD file and create welding paths with torch angles and precise parameters. The Cad file will form a work file for each fabrication project. You can create everything in the virtual work file, set all parameters, and then transfer it to robots.

Check Out – Manufacturers can make use of this application to develop simulations, manage processes and create what-if scenarios. This process will increase efficiency and productivity. It also enhances the predictability of the output and also cost-efficiency of the process. The new translation software is now popular in the market. It can automate robot programming created in the 3D model to weld every joint of the fabrication. You need to carefully review every welding joint and measure the length and size of each weld. Whether the process is sequencing, continuous or has skip welds, translation software automatically takes care of programming the robot.

Implementing Robotics Technology In Metal Fabrication

Building Information Modelling or BIM technology is now being implemented in metal fabrication. A part of 4D CAD, the software is now widely used in structural mild steel fabrication and construction. BIM was accepted as the standard about ten years ago. It facilitates data interchange between different software used for analysing, designing, detaining and finally fabricating. This format has aided the mass conversion of data from CNC machines to cutting and welding robots. It is a 4D data format with information on every part of data processing, starting from product and project definition, the geometry of each part, weld positions and other descriptive elements. Such information will allow cutting and welding robots to precisely calculate the correct tool path and the approach angles.

Today, the metal fabrication process requires robotic welding systems, CIS/2, and BIM methodology to manage the whole process efficiently. It becomes a tightly automated and integrated system that recognises different features like welds, holes and copes. The system can automatically and quickly generate weld paths for cutting, welding and scribing. The system can also simulate and evaluate different methods for automation.